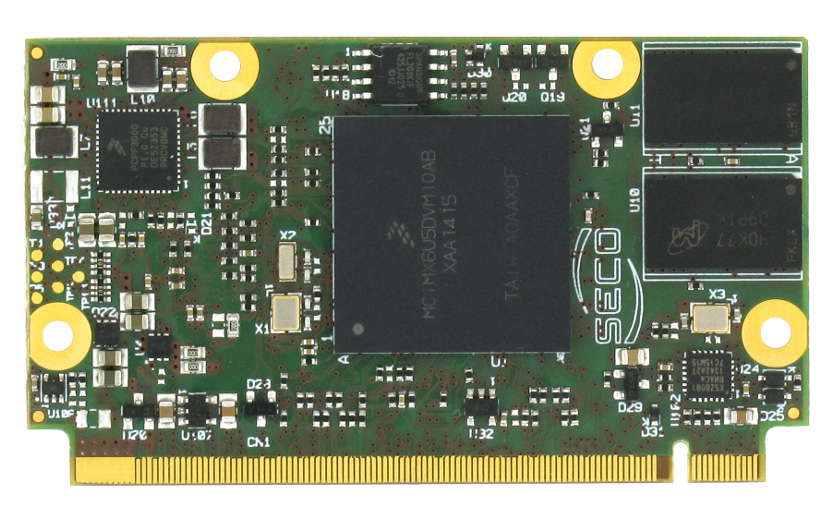

Bootlin engineer Alexandre Belloni recently worked on a custom carrier board for a Colibri iMX7 system-on-module from Toradex. This system-on-module obviously uses the i.MX7 ARM processor from Freescale/NXP.

Bootlin engineer Alexandre Belloni recently worked on a custom carrier board for a Colibri iMX7 system-on-module from Toradex. This system-on-module obviously uses the i.MX7 ARM processor from Freescale/NXP.

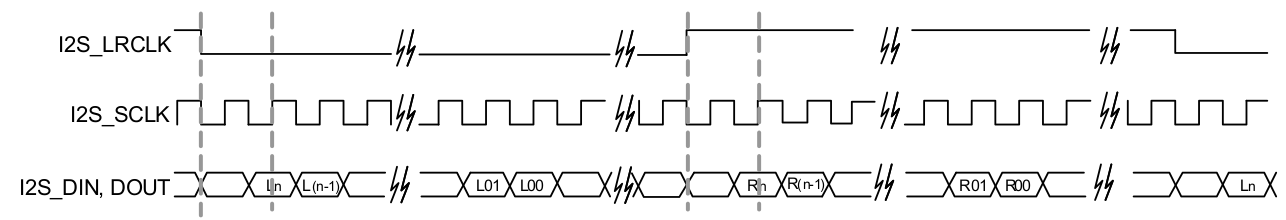

While the module includes an SGTL5000 codec, one of the requirements for that project was to handle up to eight audio channels. The SGTL5000 uses I²S and handles only two channels.

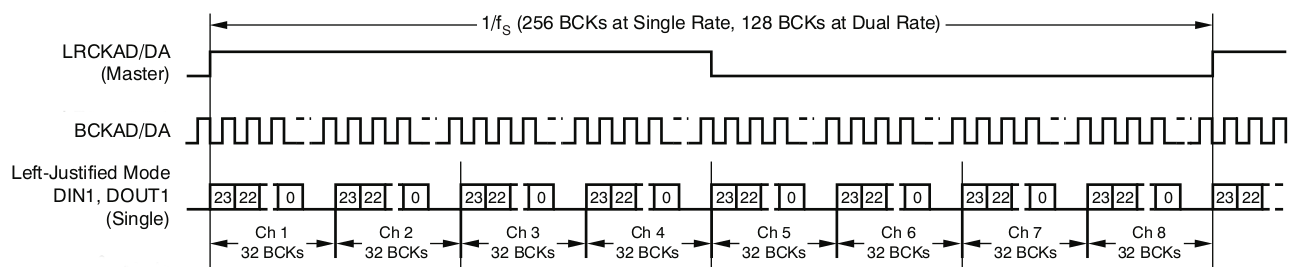

Thankfully, the i.MX7 has multiple audio interfaces and one is fully available on the SODIMM connector of the Colibri iMX7. A TI PCM3168 was chosen for the carrier board and is connected to the second Synchronous Audio Interface (SAI2) of the i.MX7. This codec can handle up to 8 output channels and 6 input channels. It can take multiple formats as its input but TDM takes the smaller number of signals (4 signals: bit clock, word clock, data input and data output).

The current Linux long term support version is 4.9 and was chosen for this project. It has support for both the i.MX7 SAI (sound/soc/fsl/fsl_sai.c) and the PCM3168 (sound/soc/codecs/pcm3168a.c). That’s two of the three components that are needed, the last one being the driver linking both by describing the topology of the “sound card”. In order to keep the custom code to the minimum, there is an existing generic driver called simple-card (sound/soc/generic/simple-card.c). It is always worth trying to use it unless something really specific prevents that. Using it was as simple as writing the following DT node:

board_sound {

compatible = "simple-audio-card";

simple-audio-card,name = "imx7-pcm3168";

simple-audio-card,widgets =

"Speaker", "Channel1out",

"Speaker", "Channel2out",

"Speaker", "Channel3out",

"Speaker", "Channel4out",

"Microphone", "Channel1in",

"Microphone", "Channel2in",

"Microphone", "Channel3in",

"Microphone", "Channel4in";

simple-audio-card,routing =

"Channel1out", "AOUT1L",

"Channel2out", "AOUT1R",

"Channel3out", "AOUT2L",

"Channel4out", "AOUT2R",

"Channel1in", "AIN1L",

"Channel2in", "AIN1R",

"Channel3in", "AIN2L",

"Channel4in", "AIN2R";

simple-audio-card,dai-link@0 {

format = "left_j";

bitclock-master = <&pcm3168_dac>;

frame-master = <&pcm3168_dac>;

frame-inversion;

cpu {

sound-dai = <&sai2>;

dai-tdm-slot-num = <8>;

dai-tdm-slot-width = <32>;

};

pcm3168_dac: codec {

sound-dai = <&pcm3168 0>;

clocks = <&codec_osc>;

};

};

simple-audio-card,dai-link@2 {

format = "left_j";

bitclock-master = <&pcm3168_adc>;

frame-master = <&pcm3168_adc>;

cpu {

sound-dai = <&sai2>;

dai-tdm-slot-num = <8>;

dai-tdm-slot-width = <32>;

};

pcm3168_adc: codec {

sound-dai = <&pcm3168 1>;

clocks = <&codec_osc>;

};

};

};

There are multiple things of interest:

- Only 4 input channels and 4 output channels are routed because the carrier board only had that wired.

- There are two DAI links because the pcm3168 driver exposes inputs and outputs separately

- As per the PCM3168 datasheet:

- left justified mode is used

-

dai-tdm-slot-numis set to 8 even though only 4 are actually used -

dai-tdm-slot-widthis set to 32 because the codec takes 24-bit samples but requires 32 clocks per sample (this is solved later in userspace) - The codec is master which is usually best regarding clock accuracy, especially since the various SoMs on the market almost never expose the audio clock on the carrier board interface. Here, a crystal was used to clock the PCM3168.

The PCM3168 codec is added under the ecspi3 node as that is where it is connected:

&ecspi3 {

pcm3168: codec@0 {

compatible = "ti,pcm3168a";

reg = <0>;

spi-max-frequency = <1000000>;

clocks = <&codec_osc>;

clock-names = "scki";

#sound-dai-cells = <1>;

VDD1-supply = <®_module_3v3>;

VDD2-supply = <®_module_3v3>;

VCCAD1-supply = <®_board_5v0>;

VCCAD2-supply = <®_board_5v0>;

VCCDA1-supply = <®_board_5v0>;

VCCDA2-supply = <®_board_5v0>;

};

};

#sound-dai-cells is what allows to select between the input and output interfaces.

On top of that, multiple issues had to be fixed:

- a small patch was added to

fsl_sai.cto make it accept more than 2 channels. It is now upstream:

https://git.kernel.org/pub/scm/linux/kernel/git/torvalds/linux.git/commit/?id=4957b556f5e7ef9855d698b7ae2f0d4245c7ff50 -

pcm3168a_hw_params()is only handling two channels in its calculations. This was solved by hardcoding a few values so nothing has been sent upstream yet. - There was an issue where the DMA would not order the samples correctly. It could not be heard using the usual 440Hz tone, but ramping down a sine shows it quite clearly:

This took most of the development effort and was solved in 4.10:

https://git.kernel.org/pub/scm/linux/kernel/git/torvalds/linux.git/commit/?id=85f57752b33cf12f1d583f0c10b752292de00abe

Finally, an ALSA configuration file (/usr/share/alsa/cards/imx7-pcm3168.conf) was written to ensure samples sent to the card are in the proper format, S32_LE. 24-bit samples will simply have zeroes in the least significant byte. For 32-bit samples, the codec will properly ignore the least significant byte.

Also this describes that the first subdevice is the playback (output) device and the second subdevice is the capture (input) device.

imx7-pcm3168.pcm.default {

@args [ CARD ]

@args.CARD {

type string

}

type asym

playback.pcm {

type plug

slave {

pcm {

type hw

card $CARD

device 0

}

format S32_LE

rate 48000

channels 4

}

}

capture.pcm {

type plug

slave {

pcm {

type hw

card $CARD

device 1

}

format S32_LE

rate 48000

channels 4

}

}

}

On top of that, the dmix and dsnoop ALSA plugins can be used to separate channels.

To conclude, this shows that it is possible to easily leverage existing code to integrate an audio codec in a design by simply writing a device tree snippet and maybe an ALSA configuration file if necessary.